- 通用电工电子实验室设备

- 维修电工实训考核装置

- 初.中.高级电工考核柜

- 电力电子实验室

- 电工电子实训考核装置

- 电工.数电.模电.电气控制装置

- 立式电工电子实验台

- 供配电技术实训设备

- 电机类实验室实训装置

- 电学技术实训与考核设备

- 汽车透明教学模型

- 汽车发动机实训台

- 汽车实物解剖模型

- 汽车新能源教学设备

- 汽车驾驶模拟器

- 汽车全车电器实验台

- 汽车仿真电路实习台

- 汽车工作原理及故障演示台

- 汽车发动机拆装台架

- 汽车变速器实验台

- 汽车红外线倒桩仪

- 汽车空调系统实验台

- 汽车底盘实训台

- 汽车发动机翻转架

- 汽车程控电教板

- 汽车示教板

- 汽车电子实验箱

- 汽车实训配套产品

- 汽车ABS/EDS/ESP实训台

- 摩托车实训设备

- 挖掘机模拟器

- 装载机.叉车教学模拟器

- 财会模拟实验室设备

- 模拟银行实训设备

- 透明电梯模型

- 机电一体化实训设备

- 机械陈列柜

- 机械实训台

- 机械创新实验设备

- 机械仿真设计综合试验装置

- 机械构造实验台

- 机床电气实训考核设备(半实物)

- 机床电气考核设备

- 数控机床实训设备

- 数控电气控制与维修实训台

- 钳工实训室设备

- 焊工、铆工实训室设备

- 电子工艺实训设备

- 制冷制热实训设备

- 中央空调实训设备

- 采暖通风实训装置

- 煤矿安全技术培训考核设备

- 流体力学实验装置

- 热工类实验装置

- 环境工程实验装置

- 物理实验室设备

- 化学实验室设备

- 生物实验室设备

- 劳技实验室设备

- 通用技术实验室设备

- 语音实验室设备

- 物流实验室设备

- 探究实验室设备

- 基础物理实验仪器

- 智能楼宇实训设备

- 单片机技术实验装置

- 计算机原理实验室设备

- 传感器综合实验台

- PLC编程及自动化实验室

- PLC可编程实训装置

- 气动液压综合实验台

- 气动实验台

- 液压实验台

- 电气设备安装调试与维修实训设备

- 工业自动化实训设备

- 变频调速实验装置

- 技师培训实训设备

- 轨道交通实验实训设备

- 船舶工程技术实训实验室

- 智能交通实训设备

- 过程控制工程实验设备

- 工程制图桌

- 化工工程.化工工艺实验装置

- 生物工程实验实训设备

- 化工原理实验装置

- 新能源教学设备

- 透明注塑机模型

- 家电实验室设备

- 工程机械教学实训台

- 中央实验台

- 教学软件

- 通信、电子类实验箱

- 教学挂图

- 心肺复苏急救模拟人

销售地址:上海市俞泾港路11号6楼

电话:021-56033369,56032405

传真:021-56776637

邮编:200072

联系人:徐建静 13901836475

24小时服务热线 18616506888

ZY-8032 博世电控柴油共轨发动机实验台

产品简介:

尺寸:1400×1000×1900(长×宽×高)

使用环境:温度-5℃~40℃;湿度≤80%

发动机类型:长城哈弗发动机,

发动机型号:TCI

排量:2.8L

机油等级:API(美国石油学会)标准SG级,

蓄电池:免维护蓄电池

万向自锁脚轮台架活动灵活,并带有自锁装置,便于移动教学;整体台架采用刚性结构焊接,所用材料如方管、角钢等采用国标标准材料,支撑可靠,并布有减震元件;表面喷塑处理防腐蚀抗老化,不褪色

控制面板采用纯铝塑板,控制面板上绘有彩色与原车控制系统相一致的直观电控系统原理图,并配有使用说明书及实验指导书。

产品组成:

发动机总成和发动机控制单元、原车线束、仪表总成、冷却液温度传感器、油轨压力传感器、曲轴位置传感器、空气流量计、点火开关、整套散热机构、汽油箱和汽油泵总成、蓄电池、五个数字电压表、真空压力表及燃油压力表、带有完整彩色电路原理图面板、外接式检测端子、智能故障设置盒总成、可移动台架、使用说明书及实验指导书等。

功能特点

本实验台可使学生了解发动机的基本构造及工作原理,通过实物认识各传感器及执行器的位置及工作原理。

通过显而易见的电脑检测端子,配合万用表检测如冷却液温度传感器、油轨压力传感器、曲轴位置传感器、凸轮轴位置传感器、空气流量计等各传感器和执行器的电压及电阻值。

设置发动机常见故障,通过故障显示,进行学生故障分析、检测诊断实训,培养学生故障分析检测诊断思维能力

显示功能

可通过原厂组合仪表、可以看到发动机的转速,及其它指示灯的工作情况. 可以通过故障指示灯来显示故障

数字表、指针表等可直观地看到各个传感器等的电压随着负载不同而变化的情况,实时显示发动机的动态、静态信号参数

通过压力表显示燃油、真空表显示进气真空压力的实际数据;还可以看到进气真空度随负载而变化的情况

LED电压表实时显示传感器变化,喷油器脉冲LED灯显示,有喷油脉宽表(实时信号)

检测功能

配备电脑数据检测端口,可通过连接专用或通用型解码器,进行各传感器、执行器及电控单元的信号检测与分析;对发动机电控系统进行ECU编码查询、故障码读取、故障码清除、动态数据流读取、波形分析、波形显示执行元件测试系统登录等

▲智能化故障设置和考核系统要求:

1)配有网络型智能化故障设置和考核系统:①采用数字化集成电路板及最新MCU技术与配套的故障设置控制技术;

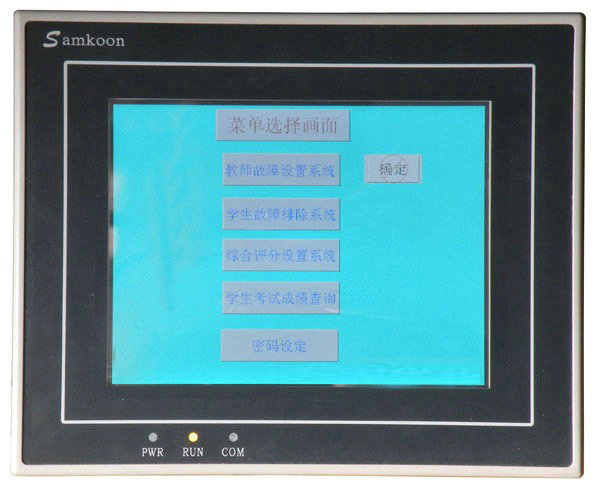

②不需要电脑就可独立进行考试考核,老师与学生界面分开,老师通过密码进入教师界面出题,学生在普通界面答题;

带有与设备相适应的试题库,试题库可根据用户的要求进行编辑;

④具有高清淅 (0.225×0.225点) 3.8寸(含3.8寸)以上的液晶显示屏,中文菜单式操作界面,人机对话友好;

⑤操作按键少,操作简单快捷;

⑥可自由设定任意一处电路的线路断路、对地短路、接触不良等故障现象;能够设置与控制模块脚有关的各种常见故障;

⑦可根据设备使用要求调整故障设置点的数量和类型;

⑧安装有RJ45网络接口,备有RS-232串行口,可用网线与其它设备的故障设置装置组成一个网络,通过主控计算机控制每一台设备的故障设置、故障排除、参数设定、远程起动、信息反馈、考核评分等功能。

2)带网络型智能化故障诊断和考核平台接口,与网络型智能化故障设置和考核系统对接后可实现以下功能:①可编辑试题及答案、试题存盘、导入试题,每道试题包括的信息:试题序号、试题描述、答案、是否要求答题限时、限时时间、答案输入次数限制;②可对班级每个学生的考试成绩进行统计,形成班级成绩报表(学生姓名、报考级别、考试成绩);③可设置系统登陆密码:新建用户和密码设置与更改;④能自动收卷、自动阅卷,能对考生的考试情况和考试成绩进行统计,帮助教师准确、全面地了解学生对各课程内容的掌握情况。

Product synopsis:

Size: 1400 x 1000 x 1900 (long x wide x high)

Use environment: temperature-5 ℃ ~ 40 ℃; Humidity 80% or less

Engine type: the Great Wall harvard engine,

Engine type: TCI

Emissions: 2.8 L

The oil level: API (American petroleum institute (SG) the standard level,

Battery: free maintenance battery

Universal locking casters, with flexible test bench activities self-lock device, and convenient to move teaching; The overall test bench with rigid structure welding, such as square tube, the materials such as gb standard materials with Angle steel, support and reliable, and cloth has a suspension component; Plastic-sprayed surface processing anti-corrosion anti-aging, not faded

Control panel is pure aluminum-plastic plate, the control panel painted with the original color car control system of electric control system consistent intuitionistic principle chart, and equipped with instructions and experimental instruction.

Composition of the product:

Engine assembly and engine control unit, the original vehicle wire harnesses, instrument assembly, cooling fluid temperature sensors, fuel rail pressure sensor, the crankshaft position sensor, air flow meter, the ignition switch, heat of a complete set of institutions, the petrol tank and petrol pump assembly, batteries, five digital voltmeter, vacuum pressure gauge and fuel pressure gauge, complete with the color of the circuit principle diagram panel, external type testing terminals, intelligent fault setting box of assembly, mobile test bench, use the description and experimental instruction, etc.

Function characteristics

This experiment platform it can make students understand the basic structure of the engine and its working principle, and through the visual know the sensors and actuators position and working principle.

Through the obvious computer terminals, with a multimeter detection test such as cooling fluid temperature sensors, fuel rail pressure sensor, the crankshaft position sensor, the camshaft position sensor, air flow meter and so on various sensors and actuators voltage and the resistance value.

Set the engine common faults, through the fault display, students fault analysis and detection diagnosis training, training students' fault analysis detection diagnosis thinking ability

display

But through the original factory combination instrument, can see the speed of the engine, and other light work. Can through the failure indicator to display the fault

Digital watch, pointer table can be intuitive to see each sensor etc with different load voltage and changing circumstances, real-time display engine to the static and dynamic signal parameters

Through the pressure gauge shows fuel, vacuum table shows the real data of the intake vacuum pressure; Also can see the vacuum degree with load and changing circumstances

The LED the voltmeter real-time display sensor changes, injector pulse LED lamp, showed a injection pulse width table (real-time signal)

Detection function

Equipped with computer data detection can be connected through the ports, special or general type decoder, in various sensors, actuators and electronic control units for signal detection and analysis; Electric control system of engine ECU coding inquiry, fault code read, fault code elimination, dynamic data flow read waveform analysis, waveform display, test execution element system login, etc

▲ intelligent fault setting and examination system requirements:

1) with intelligent network fault setting and examination system: (1) using digital integrated circuit board and the latest technology and supporting the fault of MCU control technology; set

(2) don't need computers can independently testing, the teacher and students, the teacher separated interface through a password to enter the questions on the teachers, students in the common interface interface the answer;

With and equipment that adapt to the examination test database, according to the requirements of the customers editing;

(4) have hd childen (0.225 x 0.225 3.8 inch (including some) 3.8 inches) above the liquid crystal display (LCD), Chinese menu type interface, the man-machine dialogue friendly;

(5) operation, simple operation shortcut buttons less;

6 can be free to set any one place of the circuit breaker line of short circuit, poor, contact fault phenomenon; Ability to set and control modules of various common faults on foot;

7 but according to equipment use require the adjustment fault setting the amount and type of;

8) installation RJ45 network interface, equipped with RS 232 serial port, can use Internet and other equipment fault setting up a network device, through the main controlling computer control each of the equipment fault setting, troubleshooting, set parameters, remote starting, information feedback, assessment rating etc. Function.

2) take a network intelligent fault diagnosis and examination platform, and intelligent network interface fault setting and examination system can realize the function after docking: (1) can edit test and the answer, exam inventory, and importing questions, each exam question including information: try serial number, exam description, the answer, whether to ask the answer limit, limited time, answer input number limit; (2) for each class to student test scores, form the statistical report (grades class students name, enter oneself for an examination level, test scores); (3) can be set landing system password: new users and password and change; (4) can automatic stacking, automatic scoring, can the candidates test and examination results statistical, helps the teacher to accurate, comprehensive understanding of the course content of the students master the situation.

- 上一篇:时代超人电控发动机拆装运行实训台

- 下一篇:哈弗共轨电控柴油发动机实训台